I'm about ready to send my '55 265 block out for re-build. I've read some of the recent posts about camshafts and oiling issues, but I'm a little confused. The camshaft out of the engine has the flat machined surface on it, but it needs to be replaced, along with the lifters, etc.

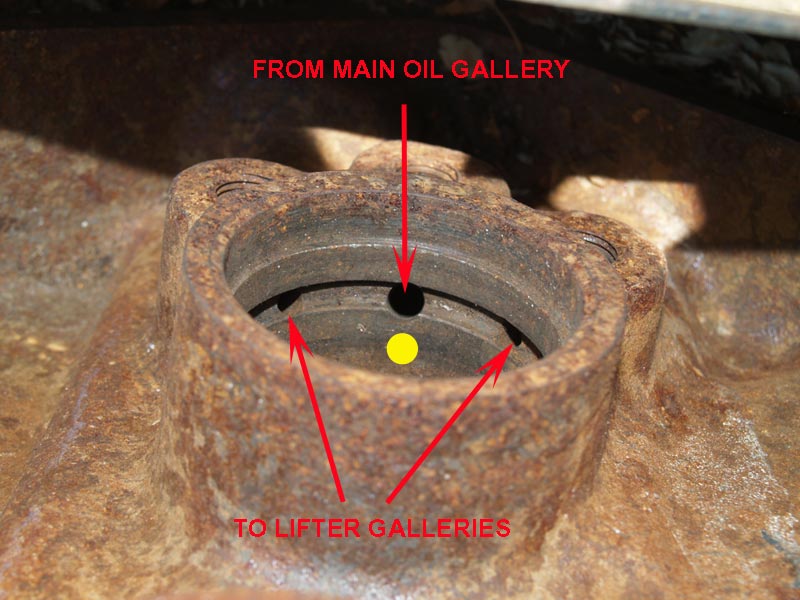

If I understand the stock oiling system correctly the 265 cam has the flat machined space on the camshaft rear bearing surface and the rear cam bearing has 2 holes? I also recall some mention of the lifters being different?

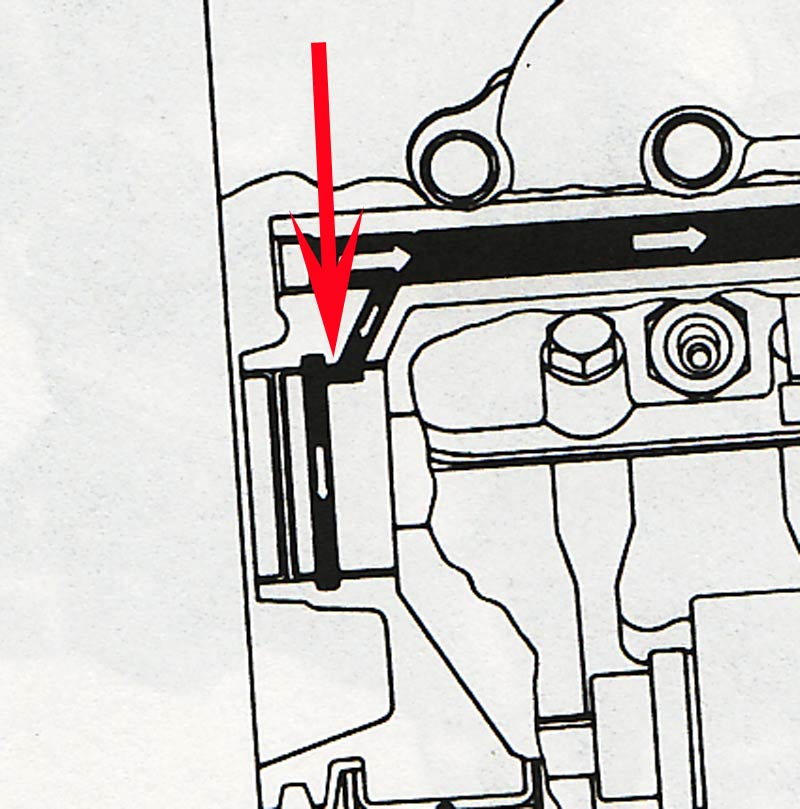

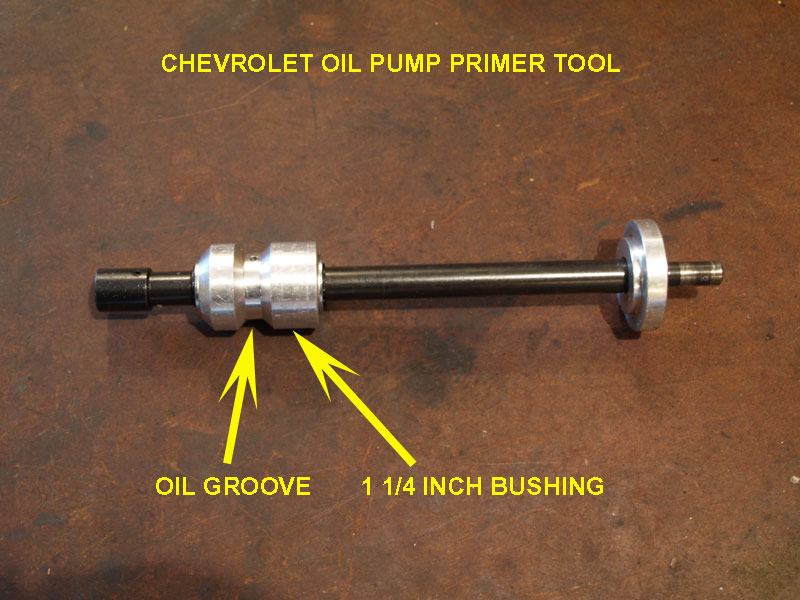

There has also been some mention of changing the oiling system to a 'full pressure' system, but what are the exact steps and parts needed to accomplish that?

The engine will be using a stock 4 bbl carb with duals.

If I understand the stock oiling system correctly the 265 cam has the flat machined space on the camshaft rear bearing surface and the rear cam bearing has 2 holes? I also recall some mention of the lifters being different?

There has also been some mention of changing the oiling system to a 'full pressure' system, but what are the exact steps and parts needed to accomplish that?

The engine will be using a stock 4 bbl carb with duals.