Just curious

Who was the OEM paint supplier for Chevrolet in 1955

Rustaddict

Discussion starter

8,249 posts

·

Joined 2011

- Add to quote

Just curious

62,313 posts

·

Joined 2008

The exterior paint charts http://www.trifive.com/specs/19. Original Specs.pdf say Dulux and Duco :confused0024:

6,657 posts

·

Joined 2009

...both of which were DuPont trademarked names for enamel and lacquer, respectively...

http://chevy.oldcarmanualproject.com/1929_57chevyparts/57cmpc1125.htm

http://chevy.oldcarmanualproject.com/1929_57chevyparts/57cmpc1127.htm

http://chevy.oldcarmanualproject.com/1929_57chevyparts/57cmpc1128.htm

Note that DuPont is no longer the owner of the Dulux trademark: http://tmsearch.uspto.gov/bin/showfield?f=doc&state=4810:dre4zd.2.21

and, Duco as a paint trademark has expired: http://tmsearch.uspto.gov/bin/showfield?f=doc&state=4810:dre4zd.3.11

http://chevy.oldcarmanualproject.com/1929_57chevyparts/57cmpc1125.htm

http://chevy.oldcarmanualproject.com/1929_57chevyparts/57cmpc1127.htm

http://chevy.oldcarmanualproject.com/1929_57chevyparts/57cmpc1128.htm

Note that DuPont is no longer the owner of the Dulux trademark: http://tmsearch.uspto.gov/bin/showfield?f=doc&state=4810:dre4zd.2.21

and, Duco as a paint trademark has expired: http://tmsearch.uspto.gov/bin/showfield?f=doc&state=4810:dre4zd.3.11

2,512 posts

·

Joined 2006

Why different?

So the bodywork received Duco laquer, and the wheels and wheel striping received Dulux enamel, but why? Was it because wheels could be easily baked for a more durable finish? :hmmmm2:

So the bodywork received Duco laquer, and the wheels and wheel striping received Dulux enamel, but why? Was it because wheels could be easily baked for a more durable finish? :hmmmm2:

17,978 posts

·

Joined 2013

The lacquer used on our classic chevys was nitrocellulose lacquer, which was extremely 'soft'... that might have been the reason for using enamel on the wheels.

Note: In 1957, some of the new metallic colors began to be painted using acrylic lacquer.

Note: In 1957, some of the new metallic colors began to be painted using acrylic lacquer.

41,673 posts

·

Joined 2007

Lacquer was baked and "reflowed" on factory paint jobs, that's why they had a smooth finish that didn't require the usual cut and buff like an aftermarket lacquer job does.

I still say that they had more than one paint supplier - competition is good for business, and keeps the supply lines full if a supplier factory goes down due to a fire or a weather disaster.

I still say that they had more than one paint supplier - competition is good for business, and keeps the supply lines full if a supplier factory goes down due to a fire or a weather disaster.

6,657 posts

·

Joined 2009

I've got DuPont and Ditzler charts for all 3 years. Unfortunately, the scans are way too big to upload.

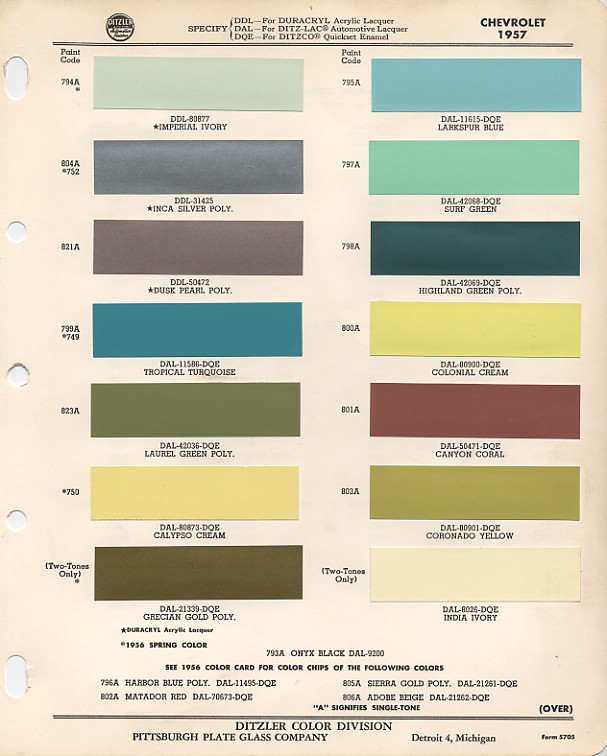

On p. 15 of the April 1956 Chevrolet Service News, it states that DuPont developed the new acrylic lacquers being introduced with the spring 1956 colors. The Ditzler spring 1956 update incorrectly lists them as nitrocellulose, but correctly lists the spring '56 acrylic colors in the '57 chart above.

Both the DuPont and Ditzler charts show 1957 as "mixed production", with some colors in nitrocellulose, and some acrylic lacquer. Note that the 1957 2 tone colors are carefully selected such that only one paint chemistry is used on a particular car - none of the 2 tone combinations have nitrocellulose for one color and acrylic for the other. This is why India Ivory is nitrocellulose, while Imperial Ivory is acrylic.

Note that not all spring '56 colors were acrylic, and the majority of '57 colors were not acrylic either.

Page 3 of the October 1956 Chevrolet Service News lists Imperial Ivory, Inca Silver, and Dusk Pearl as being Lucite acrylic lacquer, with the rest being nitrocellulose Duco. The same list appears on page 6 of the March 1957 News.

On p. 15 of the April 1956 Chevrolet Service News, it states that DuPont developed the new acrylic lacquers being introduced with the spring 1956 colors. The Ditzler spring 1956 update incorrectly lists them as nitrocellulose, but correctly lists the spring '56 acrylic colors in the '57 chart above.

Both the DuPont and Ditzler charts show 1957 as "mixed production", with some colors in nitrocellulose, and some acrylic lacquer. Note that the 1957 2 tone colors are carefully selected such that only one paint chemistry is used on a particular car - none of the 2 tone combinations have nitrocellulose for one color and acrylic for the other. This is why India Ivory is nitrocellulose, while Imperial Ivory is acrylic.

Note that not all spring '56 colors were acrylic, and the majority of '57 colors were not acrylic either.

Page 3 of the October 1956 Chevrolet Service News lists Imperial Ivory, Inca Silver, and Dusk Pearl as being Lucite acrylic lacquer, with the rest being nitrocellulose Duco. The same list appears on page 6 of the March 1957 News.

6,657 posts

·

Joined 2009

More fun facts about OEM paint:

Bigblock261 – Ford and Chrysler were using enamel on their cars in the 1950s. GM was taking a different route by painting the bodies in lacquer and the wheels only in enamel. What I’ve been told is – GM did this for the same reason custom cars were painted in lacquer – you got a nicer shine without the “orange peel” found in enamel. And, as we all know – shiny paint sells cars.

Another consideration on lacquer, GM, and DuPont: If you use the TESS search tool at the US Patent and Trademark Office web site (listed earlier), you’ll note that the trademark “Duco” was first used by DuPont on June 1, 1920, the trademark was filed on November 1, 1923, and officially registered on April 29, 1924. (serial # 71187804 and registration #0183504). The filing that I believe actually covered nitrocellulose lacquer was first used on August 15, 1922, trademark filed on June 7, 1924, and officially registered on October 20, 1925. (serial # 71198225, registration # 0204398)

GM and DuPont worked together to develop nitrocellulose lacquer as a replacement for the hand-brushed varnish used during this time. It took about 3 days to paint a car in varnish, and was a massive bottleneck in production. So, GM and DuPont had a long history of working together on paint. The above trademark dates are consistent with the history as I understand it.

That doesn’t mean that other suppliers weren’t used (PPG/Ditzler or Sherwin-Williams). I can’t prove that one way or another. But, I do know it’s a longstanding maxim to never mix paint brands when painting a car. So, one paint line in a given plant would pretty much need to be supplied by one vendor.

Bigblock261 – Ford and Chrysler were using enamel on their cars in the 1950s. GM was taking a different route by painting the bodies in lacquer and the wheels only in enamel. What I’ve been told is – GM did this for the same reason custom cars were painted in lacquer – you got a nicer shine without the “orange peel” found in enamel. And, as we all know – shiny paint sells cars.

Another consideration on lacquer, GM, and DuPont: If you use the TESS search tool at the US Patent and Trademark Office web site (listed earlier), you’ll note that the trademark “Duco” was first used by DuPont on June 1, 1920, the trademark was filed on November 1, 1923, and officially registered on April 29, 1924. (serial # 71187804 and registration #0183504). The filing that I believe actually covered nitrocellulose lacquer was first used on August 15, 1922, trademark filed on June 7, 1924, and officially registered on October 20, 1925. (serial # 71198225, registration # 0204398)

GM and DuPont worked together to develop nitrocellulose lacquer as a replacement for the hand-brushed varnish used during this time. It took about 3 days to paint a car in varnish, and was a massive bottleneck in production. So, GM and DuPont had a long history of working together on paint. The above trademark dates are consistent with the history as I understand it.

That doesn’t mean that other suppliers weren’t used (PPG/Ditzler or Sherwin-Williams). I can’t prove that one way or another. But, I do know it’s a longstanding maxim to never mix paint brands when painting a car. So, one paint line in a given plant would pretty much need to be supplied by one vendor.

2,512 posts

·

Joined 2006

Line of business.

Our car was last painted in 1995. Back then as I was shopping for a paint and body shop, I asked the owner of a custom paint shop to price the job using Duco/Dulux. He flat out said No and take the car elsewhere.

His recommendation then was PPG Deltron. He said it was unwise not to take advantage of 40 years of advancement in automotive finish technology if we planned to take the car out into the sun.

So it has PPG. It still looks good to us.

Thanks geek!More fun facts about OEM paint:

Our car was last painted in 1995. Back then as I was shopping for a paint and body shop, I asked the owner of a custom paint shop to price the job using Duco/Dulux. He flat out said No and take the car elsewhere.

His recommendation then was PPG Deltron. He said it was unwise not to take advantage of 40 years of advancement in automotive finish technology if we planned to take the car out into the sun.

So it has PPG. It still looks good to us.

573 posts

·

Joined 2014

I took a tour of the Baltimore plant back in 1972. While walking down the assembly line getting closer to the paint ovens, I noticed this yellow Chevelle parked between the 2 lines where we had to pass. It looked odd, as if someone had applied those flower decals that were popular back in that era to the windshield. As I got closer, I realized what happened. The windshield was delaminated, I was seeing the plastic in the glass layers. The spark plug wires were drooping off the engine, melted. Anything made of plastic was melted. The paint was gorgeous and the car was trash. Someone left the oven on over the weekend and this vehicle was inside.

Usually more than one vendor was employed to keep the assembly line running in case of strike, quality issues, or other problems that could occur. One exception is the cigarette lighter. Only one company makes them, Casco, and they are still making them.

Usually more than one vendor was employed to keep the assembly line running in case of strike, quality issues, or other problems that could occur. One exception is the cigarette lighter. Only one company makes them, Casco, and they are still making them.

32,232 posts

·

Joined 2007

Rochester also made lighters for tri-5's. See Group 9.709 in the parts book. The Casco lighter wouldn't fit the Rochester socket and vice-versa. http://chevy.oldcarmanualproject.com/1929_57chevyparts/57cmpc0666.htmUsually more than one vendor was employed to keep the assembly line running in case of strike, quality issues, or other problems that could occur. One exception is the cigarette lighter. Only one company makes them, Casco, and they are still making them.

41,673 posts

·

Joined 2007

With lacquer, mixing paint brands was not the concern it is with modern paint.

Actually a lot of painters mix brands today, but leave that to those who've done it, you don't want to be a pioneer unless it's necessary.

And whatever they used for the base primer back then was (and still is) some tenacious stuff - I think you could apply just about anything over it.

The biggest no-no on mixing types of paint back in the old days was applying lacquer over an aftermarket non-baked/non-catalyzed enamel.

Actually a lot of painters mix brands today, but leave that to those who've done it, you don't want to be a pioneer unless it's necessary.

And whatever they used for the base primer back then was (and still is) some tenacious stuff - I think you could apply just about anything over it.

The biggest no-no on mixing types of paint back in the old days was applying lacquer over an aftermarket non-baked/non-catalyzed enamel.

17,978 posts

·

Joined 2013

Absolutely correct! .. you could spray almost anything over the factory lacquer, because it's fast drying to begin with, and was factory baked... totally cured before it reached the customer, whereas enamels (especially non catalyzed ones) are very slow curing and if they are still curing (outgassing) when something it sprayed over it, the gas will pop thru.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.7M

- members

- 72K

- Since

- 2005

A forum community dedicated to 1955, 1956, and 1957 Chevy owners and enthusiasts. Come join the discussion about restoration, engine swaps, reviews, performance, modifications, classifieds, troubleshooting, maintenance, and more! Open to all models including Belair, 210, 150, Sedans, and Nomads.